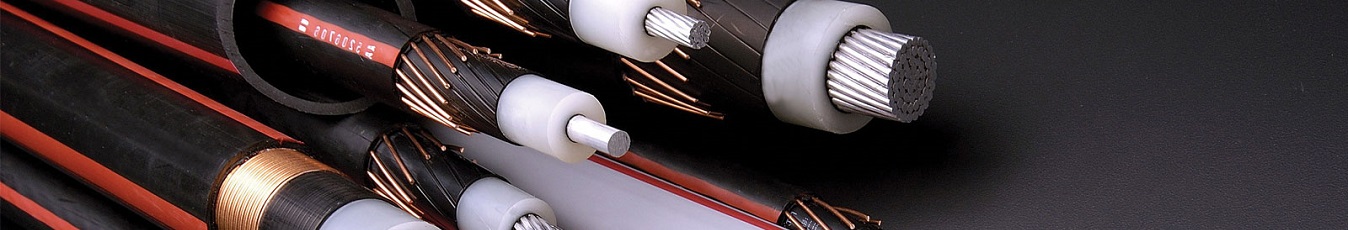

Power Cable

LT XLPE INSULATED POWER CABLES 1.1 KV

Higher Current Rating: Withstands continuous conductor temperature of 90°C, whereas PVC withstands only 70°C, which means higher current carrying capacity.

Higher Overload Capacity: cables can operate even at 130°C, during emergency, unlike PVC Cables which cannot operate beyond 120°C. Thus in an emergency, the entire system need not go out of commission if some of the cables fail, because the other cables in parallel can carry a higher load.

Higher Short Circuit Rating: Can withstand conductor temperatures of upto 250°C during a short circuit PVC cannot withstand more than 160°C.

Lighter in Weight, Smaller Bending Radius: Lighter weight, smaller bending radius than PVC enables installation of Svarn cables even in cramped space conditions. The cables require less support, thus lowering installation costs.

Lower Di-electric Constant and Power Factor: Results in saving in power losses which means saving in costs, particularly for higher voltage.

Better Impact, Abrasion, Corrosion Resistance: Safer than PVC Cables against mechanical damage,abrasion and corrosion.

Easier Jointing and Termination: Requires no special skills or equipment for jointing and termination.

| Comparison Of Properties | ||

|---|---|---|

| XLPE | PVC | |

| Dielectric Constant | 2.35 | 6 to 8 |

| Dielectric strength (KV/mm) | 22 | 14 |

| Volume Resistivity at 27°C Ohm-cm | 1014 | 1013 |

| Thermal Resistivity °C cm/W | 350 | 600 |

| Power Factor at maximum conductor temperature | 0.008 | 0.1 |

| Normal conductor operating temperature °C | 90 | 70 |

| Emergency overload temperature °C | 130 | 120 |

| Maximum short circuit temperature °C | 250 | 160 |

CONTROL CABLES

Voltage: These cables can be used on AC Voltage up to & including 1100 V or DC Upto & including 1500 V.

Size: 1.5 Sq. mm. & 2.5 Sq. mm. up to 61 Cores in Control Cable.

Conductor: Annealed Bare /Tinned Electrolytic Copper conforming to IS:8130:1984.

Insulation: Conductor are insulated with PVC Compound as per IS:5831:1984.

Color of Cores: Cores are identified with a color scheme as per IS:1554(Pt-I):1988 as under :

In case of cable exceeding five cores, two adjacent (counting and direction cores ) in each layer shall be colored Blue, Yellow and remaining cores grey/Cores can be identified by numbers by numbers printed on that of same color.

Laying of Cores: Cores are laid up with a suitable lay. The Final layer direction shall be kept right hand lay.

Inner Sheath: The Inner Sheath is applied over laid up of cores by extrusion/wrapping of thermoplastic material. The Insulation, Inner Sheath can be HR PVC, FRLS PVC or HFFR Compound depending upon their application.

Outer Sheath: A final covering of PVC Compound, conforming to IS:5831:84, is applied over Armouring in case of Armoured Cable or over Inner Sheath in case of Unarmoured Cable, called as "Outer Sheath".

The Insulation and Sheath material can be HR PVC, FRLS PVC or HFFR Compound depending upon their application.

Current Rating: Current Carrying Capacity of these cables are as per IS:3961{Pt-II) : 1967.

Standard Specifications: IS 1554:1988 (PART -1),BS:6346:1989,IEC 227-I, III.